Samsung Display A3 line replaced with Y-OCTA manufacturing line

The touch panel technology installed on a mobile phone is an important element technology that performs a user interface function. Touch technology is changed from an add-on type to an on-cell type in flexible OLED displays.

The built-in method in which a touch sensor is formed on a thin film encapsulation (TFE) is called by various names such as Y-OCTA(YOUM on-cell touch AMOLED), ToE(touch on encapsulation) or FMLOC(flexible multi-layer on cell touch) for each panel maker. Unlike the add-on type, the on-cell type touch sensor is formed directly on the top of the encapsulation layer without a separate base film. Due to this, the on-cell type has a higher process difficulty than the add-on type, but it is advantageous to manufacture a thin OLED panel thickness, and there is an effect of reducing the process cost.

Recently, in order to apply this on-cell type touch technology to mobile phones using OLEDs, each display manufacturer is undergoing a step-by-step line modification work. Four mask steps are added to apply the on-cell type touch technology. There are two ways to cope with this process step increase: to install and respond to new equipment as much as the process to increase, and to proceed with the process at existing facilities.

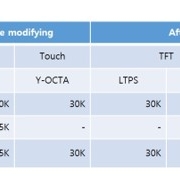

Samsung Display decided to use an existing exposure machine to use the on-cell type touch technology in the existing A3 line (Tangjeong), and is in the process of remodeling the 105K capacity TFT production line. In the existing process flow, a back plane process is performed with mother glass of 1500×1800 mm2 and 1500×900 mm2 glass with half-cutting of this mother glass is processed in the OLED process. Therefore, in order to process the half-cut glass again in the back plane equipment, the jig manufacturing method of connecting and processing two cut sheets is applied. After this modification, the production capacity of the A3 line will be reduced. The amount of 105K of the A3 line that is currently being renovated is changed from LTPS process to LTPO process, and it is combined with Y-OCTA process. In this case, 3 mask steps increase as LTPS is changed to LTPO, and 4 additional mask steps increase for Y-OCTA. As a result of the total increase of 7 mask steps, the A3 line is expected to reduce the existing 105K production capacity to approximately 75K level after remodeling.

China’s BOE is also constructing built-in touch processes in B7 and B11. BOE is in the process of adding and processing exposure equipment, etc. as a way to add a built-in touch process. In this case, there will be no significant change in production capa.

<Production capacity comparing with before/after modifying at SDC A3 line>