How far has QNED completed?

The reality of QNED (quantum dot nano-rod LED), which Samsung Display is preparing as a next-generation display, has become clear.

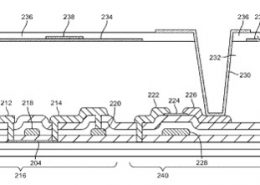

As a result of analyzing 160 patents applied by Samsung Display, it was confirmed that the structure constituting the QNED has already been completed, and that the only remaining task is to keep the number of nano-rod LEDs arranged in the light-emitting pixel constant.

OLED Market Enters Adjustment Period from Rapid Growth

As smartphone makers, including Samsung Electronics and Apple, increased the use of OLEDs in flagship models, the growth of the OLED market, which had been rapidly growing, has been braked.

The third quarter of each year is the season with the best OLED performance for smartphones due to the launch of a new iPhone. According to the display market track of UBI Research (www.ubiresearch.com), in the third quarter of this year, 113 million units were shipped, an increase of 26.3 million units compared to 86.7 million units in the last quarter, showing a growth of 30.4%. However, this figure is due to an optical illusion. The reason is that the results in the first and second quarters were very poor compared to before due to COVID-19.

Samsung Electronics’ foldable smartphone to be released in 2021, with touch pen and UTG thickness different?

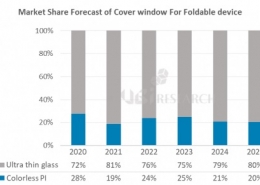

The cover window material of Samsung Electronics 'Galaxy Z Fold 2' which will be released in the second half of this year, is UTG like 'Galaxy Z Filp'. The reason why Samsung Electronics prefers UTG is analyzed for its sense of luxury, differentiation, and sensitivity for the touch pen expected to be applied in the future.

In 2021, the market for over 10 million foldable phones is expected to expand, and the main cover window material of Samsung's foldable phones will be UTG. To respond to this, Dowooinsys should increase their capacity.

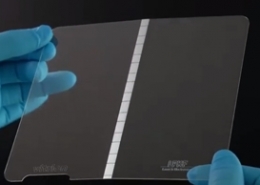

LPKF's laser glass processing technology, makes a cover glass thicker than UTG be folded.

It was expected that the S Pen would be applied to Samsung's 'Galaxy Z Fold2', which will be released in the second half of this year, but it has passed the year.

UTG, the cover window material currently applied to Samsung Electronics’ 'Galaxy Z Filp', is 30 um thick and is 1/10 thinner than 300 um, the thickness of commercially available cover glass.

Samsung Display A3 line replaced with Y-OCTA manufacturing line

The touch panel technology installed on a mobile phone is an important element technology that performs a user interface function. Touch technology is changed from an add-on type to an on-cell type in flexible OLED displays.

QNED structure and manufacturing technology analysis report published

UBI Research (www.ubiresearch.com) published “QNED Structure and Manufacturing Technology Analysis Report”, which analyzed 41 cases of Samsung Display's QNED (quantum dot nanorod LED) published patents.

The contents described in this report were selected from the 41 patents published, which are considered to be used for QNED manufacturing, and are constructed by qualitative analysis.

The next full-screen display trend is the under-display camera

Since Samsung's Galaxy S8 and Apple's iPhone X launch, smartphones with the Home button removed have become a trend in the smartphone market.

Due to the nature of smartphones that cannot grow indefinitely, display sizes with a large proportion within limited smartphone sizes are directly related to the competitiveness of smartphone set makers.

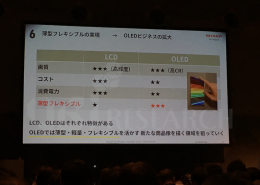

[28TH FINETECH JAPAN] Sharp, announced Future Strategy Combining IGZO and OLED

Mr. Atsushi Ban, Vice President of Sharp presented a future strategy that combines IGZO and OLED through a keynote session at the 28th FINETECH JAPAN, held in Makuhari Messe, Japan from December 5, 2018.

Apple adopts LTPO TFT to extend battery life time to Apple Watch Series 4

Apple released its Apple Watch Series 4 with enhanced healthcare features on a larger screen than before, in the Steve Jobs Theater at Apple Park in California, USA on September 12.

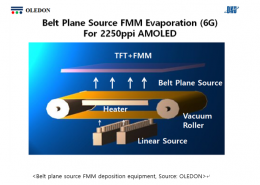

OLEDON, is to announce belt-plane source deposition technology for manufacturing ultra-high resolution and ultra-area OLED

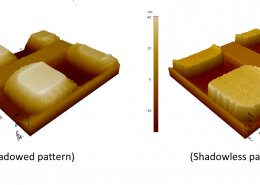

Plane source technology, which was first developed by OLEDON in the world, has the principle of depositing the first organic material on the metal surface and evaporating it upwards to produce fine pattern of 2250 ppi, which is ultrahigh resolution. In this plane source process, three processes such as the first deposition, the plane source inversion, and the second evaporation are necessary, and the number of the high vacuum chambers is increased when the mass production is applied. The belt plane source FMM deposition technology introduced by OLEDON has a concept of carrying out the above processes at a time in one evaporation equipment. This is a continuous plane source supplying deposition technology in which the metal surface is formed in a belt shape.

OLEDON unveils plane source deposition technology for 'super-gap' OLED manufacturing.

Attention is growing since OLEDON, a venture company developing OLED deposition equipment, unveiled plane source deposition technology for OLED manufacturing to maintain ‘a superb gap with the competing countries’, at IMID2018, held in COEX, Seoul, Oct. 24, 2018.

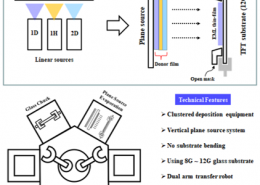

OLEDON develops vertical plane source deposition technology for large OLED TV manufacturing

Hwang Chang-Hun, CEO of OLEDON, which has developed plane-source deposition technology for small & medium-sized OLED and large area OLED, said that it is under development of vertical plane source deposition technology capable of manufacturing ultra-large OLED TVs of 77 inches or larger