78.6 tons of OLED emitting material demand increased by 5.6% in 2020

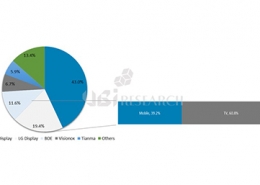

According to the 2020 OLED emitting material report published by UBI Research, the demand for emitting materials in 2020 is 78.6 tons, which is 4.2 tons higher than last year's 74.4 tons. The material used for OLEDs for smartphones and mobile devices is 62.9 tons, and the OLED emitting material for TVs is expected to be 15.7 tons.

JDI decided to sell LCD production equipment to a foreign client for 200 million dollars.

JDI announced that it has agreed to sell production equipment at its plant in Hakusan, Ishikawa Prefecture, to a foreign client for 200 million dollars. The Hakusan plant was JDI's mainstay factory, producing LCD panels for Apple. The plant was halted in July last year due to sluggish demand. JDI plans to clean up excess facilities that have caused poor performance.

Wuhan Tianma 6G OLED line installation delay

The Tianma T4 plant in Wuhan has continued to produce even during the corona period, and the core equipment of the ph2 6G OLED line has already been brought in, but the equipment set-up is delayed due to the inability of overseas equipment companies to enter Wuhan.

2020 OLED Manufacturing Equipment Market Forecast

According to UBI Research's annual equipment market track for 2020, the OLED manufacturing equipment market is expected to reach $ 9.51 billion in 2020. This is an increase of $ 0.03 billion compared to $ 9.48 billion in 2019.

AP System supplies ELA equipment to Chongqing BOE B12

AP System was selected as the final bidder for BOE's B12 line ELA (eximer laser annealing) equipment. ELA is an essential equipment to make low temperature polysilicon (LTPS) TFT for OLED. Eximer laser crystallizes a-Si into polysilicon. It is called LTPS because it makes polysilicon without applying high heat.

Samsung Display decided to invest 13 trillion won in QD-OLED by 2025

Samsung Display chose QD-OLED as the next generation premium TV. It will also have a big impact on the premium TV market, which is divided between white OLED technology and QLED technology.

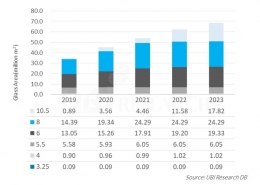

[Press Release] OLED production capacity will increase to double in 2023.

UBI Research has published [2019 OLED Equipment Report] that forecasts the OLED equipment market. According to the report, the total substrate area of display companies in 2019 will be 34.9 million square meters, which will be 68.5 million square meters in 2023 and double after four years.

2019 Chinese OLED panel maker equipment order status

As Korean OLED panel makers do not have a lot of investment, the OLED equipment industry is in a low-demand season. When Chinese OLED panel makers confirm the order status of equipment orders in 2019, orders are being made centering on equipment and module line equipment required for new technologies rather than new lines.

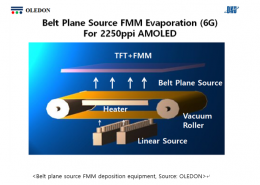

OLEDON, is to announce belt-plane source deposition technology for manufacturing ultra-high resolution and ultra-area OLED

Plane source technology, which was first developed by OLEDON in the world, has the principle of depositing the first organic material on the metal surface and evaporating it upwards to produce fine pattern of 2250 ppi, which is ultrahigh resolution. In this plane source process, three processes such as the first deposition, the plane source inversion, and the second evaporation are necessary, and the number of the high vacuum chambers is increased when the mass production is applied. The belt plane source FMM deposition technology introduced by OLEDON has a concept of carrying out the above processes at a time in one evaporation equipment. This is a continuous plane source supplying deposition technology in which the metal surface is formed in a belt shape.

OLEDON unveils plane source deposition technology for 'super-gap' OLED manufacturing.

Attention is growing since OLEDON, a venture company developing OLED deposition equipment, unveiled plane source deposition technology for OLED manufacturing to maintain ‘a superb gap with the competing countries’, at IMID2018, held in COEX, Seoul, Oct. 24, 2018.

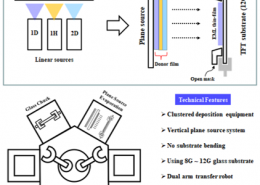

OLEDON develops vertical plane source deposition technology for large OLED TV manufacturing

Hwang Chang-Hun, CEO of OLEDON, which has developed plane-source deposition technology for small & medium-sized OLED and large area OLED, said that it is under development of vertical plane source deposition technology capable of manufacturing ultra-large OLED TVs of 77 inches or larger

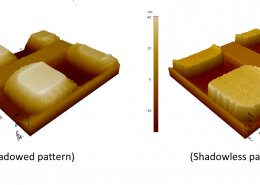

[IMID 2018] OLEDON, developed ‘curved plane source FMM deposition technology’ for 2250ppi AMOLED for the first time in the world

OLEDON is a company which develops plane source deposition technology for high resolution AMOLED manufacturing. Hwang Chang-Hoon, CEO of OLEDON announced in IMID 2018 that it developed ‘curved plane source FMM deposition technology’ that can be adopted to 2250ppi AMOLED pixels, for the first time in the world.