If the 600ppi Soluble process OLED is to be possible?

As a company producing ink-jet equipment for the soluble process OLED, Seiko Epson has already developed the ink-jet head which could realize up to 360ppi by arranging the 180ppi nozzles in 2 rows. Given that the resolution of the evaporation method RGB OLED is still in the 260ppi as a real RGB, it is a significantly useful technology in the development of high-resolution display.

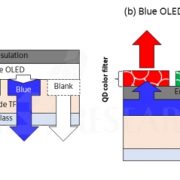

Seiko Epson developed the technology to maintain total amount of ink in a fixed rate per pixel with the ink volume control and multiple nozzles, and also holds the technology to apply emissive layer evenly on the entire surface of HTL by making the surface of HTL and the contact angle of separation equal. In addition, the productions of the bottom emission OLED as well as the top emission OLED were succeeded in ink-jet. Top emission is possible when the HIL thin layer is applied extremely evenly using special combination of ink as the thickness of HIL layer influences greatly on the optical character.

Seiko Epson is planning to develop the 600ppi ink-jet head that arranges the 400ppi nozzles in two rows in order to develop the equipment producing hyper-resolution soluble process OLED. It is anticipated if it is possible to manufacture a hyper-resolution OLED of 600ppi, it will be the moment to replace LCD in the mobile display area for it could easily resolve the greatest weakness of OLED which is high-resolution issue.