What is Solution Process OLED’s Key Issue?

In the 2015 Display Printed Electronics Seminar held in The K Hotel in Seoul on October 7, Dankook University’s Professor Byung Doo Chin and Korea Research Institute of Chemical Technology’s Dr. Jaemin Lee gave presentations. They discussed key issues of solution process OLED; Professor Chin examined technological issues of print OLED/PLED device while Dr. Lee discussed technology trend of solution process OLED device.

Professor Chin reported that of the materials being used in current solution process, red, and green progressed greatly in terms of efficiency and lifetime. However, he explained that as blue’s efficiency and lifetime are lower than the other 2 colors, unless these issues improve, white actualization, as well as blue actualization, is difficult and panel cannot properly perform.

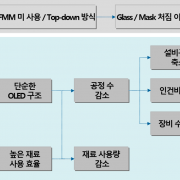

Material research development can occur for evaporation OLED only through material synthesis and purification. However, for solution process OLED, turning the materials to ink has to be additionally considered. Dr. Lee announced that diverse collaboration are happening between material and ink related companies for these reasons.

In the seminar, Professor Chin and Dr. Lee agreed that the key to the solution process OLED development is material characteristics development. According to the solution process material traits presented by Sumitomo Chem. and DuPont, while red and green traits are fast catching up to ones used for evaporation OLED, this is not true for blue. Despite these disadvantages, solution process OLED is a key technology that can produce large area RGB OLED panel using Gen8, or higher, manufacturing equipment; continued research development of solution process technology is expected in future.