[Analyst Column] Watch issued for the promotion of QD-LED BLU LCD TV

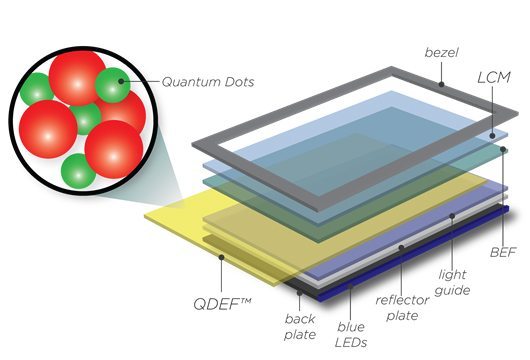

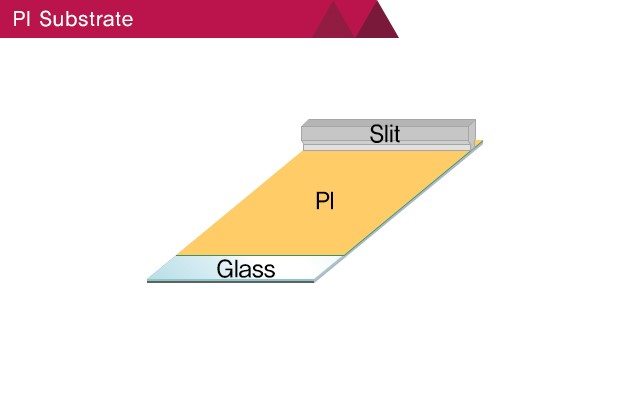

Lately, the media, research institutes and stock firms are scrambling to release data on the marketability of QD-LCD TV which is the LCD TV applying the QD (quantum dot) materials to the LED backlight. In the strict sense, it is not a LCD technology but a backlight technology. The QD-LCD BLU (backlight unit) can be divided into the three types; one is applying the QD material directly to the LED chip, another is arranging it in front of the LED chip; and lastly it is placing it in between LCD and Light Guide Plate after filming by inserting the QD materials to the barrier film.

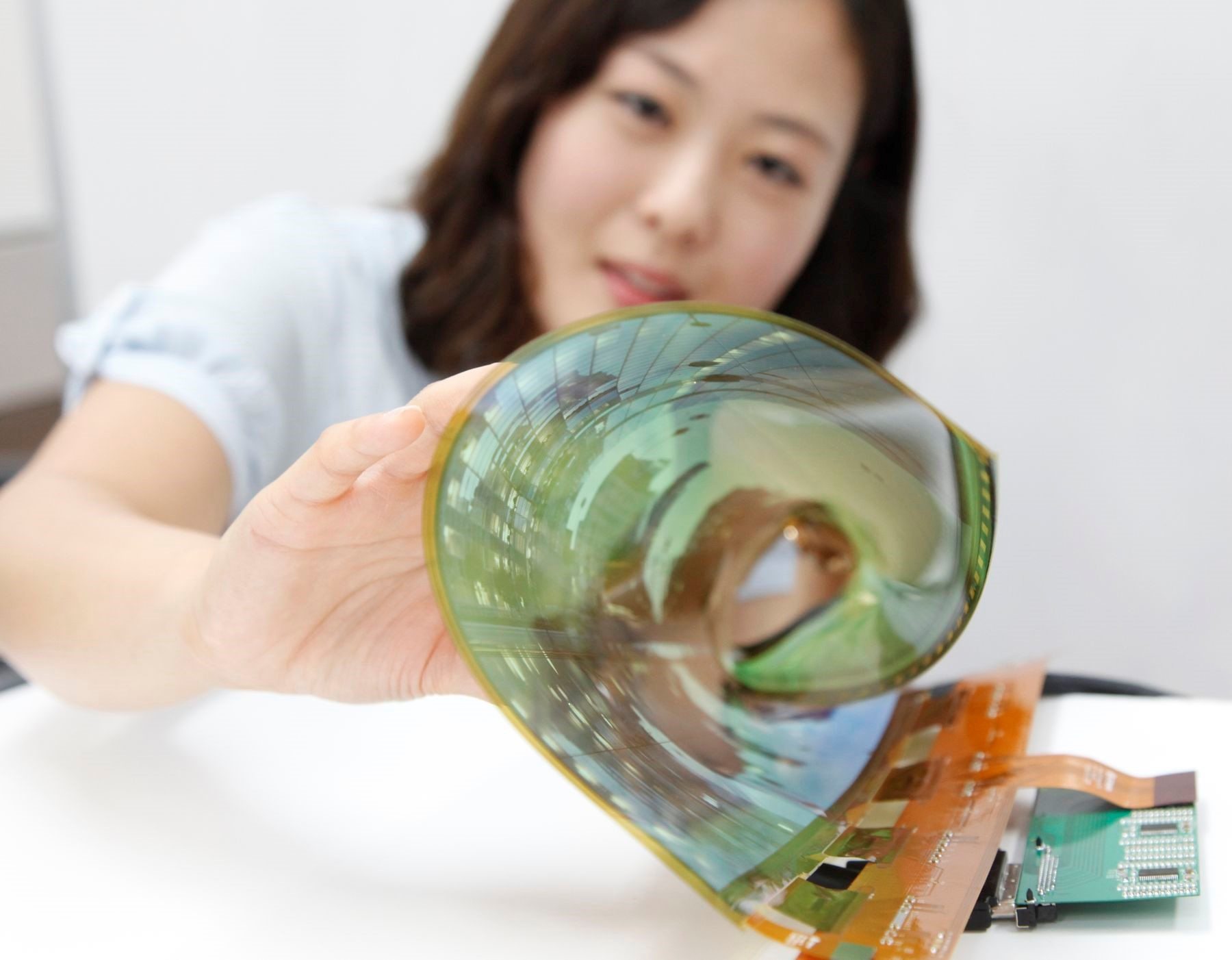

Source: Wikimedia,

http://commons.wikimedia.org/wiki/File:QDEF_Exploded_Diagram.png

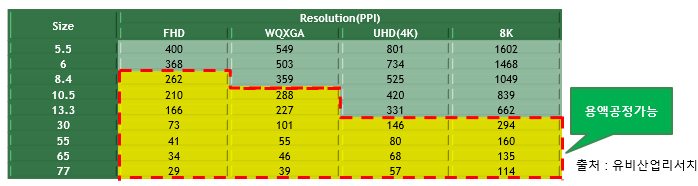

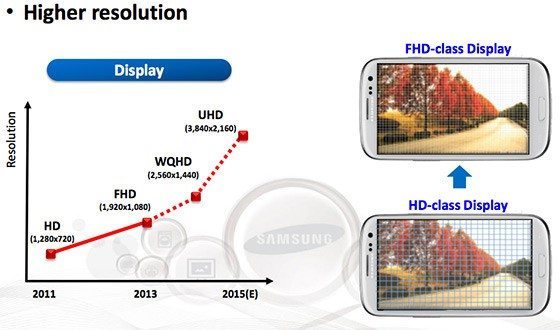

The QD-LED BLU is being recognized as a LCD TV technology that can compete with the OLED TV as it has a merit to improve the color reproducibility up to about 12 percent compared to the existing LED BLU. Until now, the LCD TV manufacturers take the notion of resolution as a major marketing means to compete with other products like PDP. And it was the same with the OLED case. However, the Apple iPhone highlighted the resolution as the biggest difference with the Galaxy S of Samsung Electronics but Samsung Electronics counter attacked with the color reproducibility as overcoming the resolution issue with the pentile technology, ranking the first in the market share. The LCD TV part, presenting the 4K and 8K TVs continuously, expected that the OLED TV won’t be able to catch up but LG Display is planning to come into the market from 2015 as developing the 4K OLED panel in the 55-inch with the oxide TFT and WRGB OLED technologies.

Given that the superiority of the OLED panel’s picture quality over that of LCD was verified through Samsung Electronics’ Galaxy S and LG Electronics’ OLED TV, the best way to defense for the companies with no available OLED TV to sell is the early release of QD-LED BLU LCD TV with the improved color reproducibility.

The products applying new technologies have been well received in the market. The problem is that promoting the QD-LED BLU LCD TV to the extent of highlighting excessively may cause the distortion of a market or capital. For instance, the domestic stock firms are indeed reporting that the QD-LED BLU LCD TV as a highly eco-friendly product with an efficient energy consumption. But it is known that the brightness of the QD-LED BLU LD TV is 30 percent less than the existing LED BLU LCD TV. If the brightness decreases, it requires more LED chip and more driving modules as well, raising the production cost. Moreover, it emits more heat in proportion to the added amount of LED chips, increasing the corresponding cost for heat dissipation.

It is expected that the application of the QD-LED BLU will be limited to the premium products as there are numerous factors causing the increase of the production cost in varied channels. Though it is true that the QD-LED BLU can provide better picture quality than the LCD TV, it must be clarified that it is not the product surpassing the LCD TV.

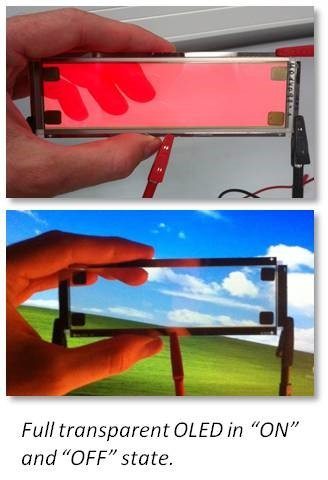

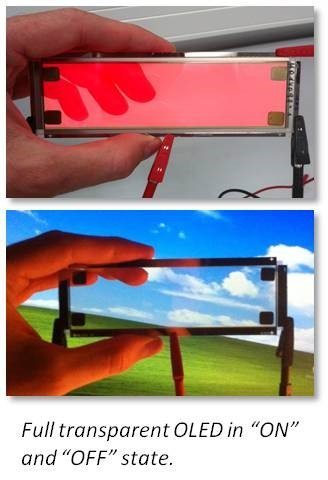

And the careful attention of various media in using the name ‘QD TV’ is needed in that it might confuse general customers. The QD technology is also a very fascinating and appealing technology for the OLED developers. They are already developing the OLED panel using the QD materials and the blue elements in the field of OLED panel manufacturing technology. Then, this OLED TV eventually becomes the QD TV. Accordingly, it must be noted that any reports written without the clear understanding of QD may cause a considerable social repercussion in the display market.

Choong-hoon Yi / Chief Analyst / UBI Research ubiyi@ubiresearch.co.kr