[LED/OLED EXPO 2015] Low Cost OLED Lighting Panel Production, QD Film Provides the Solution?

One of the reasons that OLED lighting is not becoming commercialized, despite its diverse advantages compared to other lightings, is its high price. The most fundamental way to reduce OLED lighting panel cost is investment in OLED lighting panel mass production line. Price reduction for components and materials is also an important factor.

The OLED lighting panel that is currently being mass produced has red/green/blue or yellow/blue stack structure. Also the use of tandem structure of more than 2 stacks to increase efficiency makes the process complex, lowers the yield, and increases the amount of materials used, and is becoming a key factor in increasing the production cost.

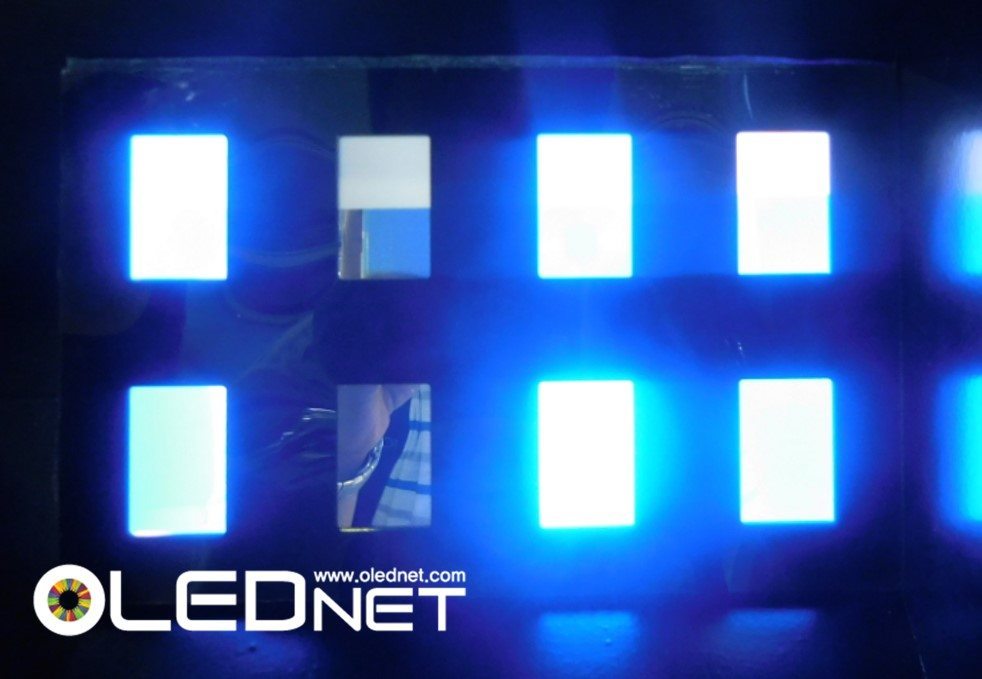

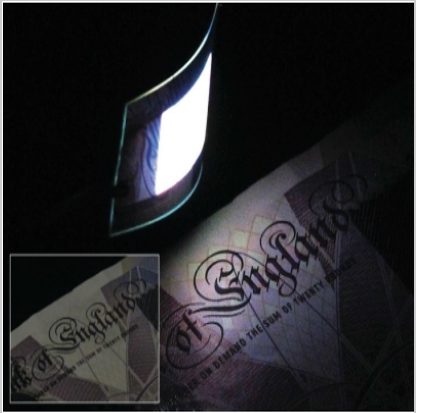

At LED/OLED Expo 2015, Cheorwon Plasma Research Institute (CPRI) displayed technology that produces white by applying light extracting film that contains red and green quantum dot (QD) material on blue OLED. CPRI forecasts that this technology of QD film applied blue OLED will be the solution for lowering OLED lighting panel production cost.

CPRI’s senior researcher Yong Hwan Yoo explained, “When QD light extracting film is applied to blue OLED, the evaporation processes are reduced compared to existing RGB or YB tandem structure OLED lighting. This could lead to production cost reduction as the yield increases and material cost decreases. If the QD purity improves, as well as blue material’s lifetime and efficiency, it is anticipated that the efficacy will match that of RGB or YB tandem OLED lighting panel.”

CPRI exhibited LED caps to be used for mascots at the opening/closing ceremonies of PyeongChang 2018 Winter Olympics, ultimately aiming for manufacturing them using OLED lighting panel instead of LED.