Silicone Better than Acrylic for Flexible OLED…Momentive Introduces InvisiSil

Momentive demonstrated InvisiSil at SID 2016 (Source = Momentive)

Hyunjoo Kang / jjoo@olednet.com

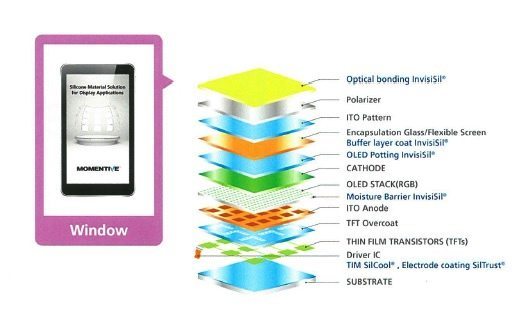

One of the issues of flexible OLED actualization is acrylic’s vulnerability against lower temperature, and silicone is emerging as a solution. Meanwhile, Momentive is attracting attention with their promotion of silicone based InvisiSil.

One of the key encapsulation technologies for flexible OLED is TFE (thin film encapsulation) that laminates thin inorganic and organic films, used by Samsung Display. Of these, organic material is formed through inkjet OLED process using acrylic materials. However, acrylic organic materials are easily broken under 0 ℃, which leads to difficulties in producing flexible OLED using these. However, silicone based materials can withstand up to -40 ℃ and are considered strong candidate for acrylic replacement.

Momentive is a company that develops such silicone based materials. In SID 2016 (22-27 May), Momentive opened an exhibition booth and presented InvisiSil Snap Cure silicones. The InvisiSil Snap Cure systems can cure rapidly at room temperature without UV exposure.

Momentive explained that for flexible AMOLED panel to move past edge type and toward true flexible such as foldable and rollable, silicone is much better suited than acrylic. Furthermore, they added that silicone based materials have yet revealed any disadvantages compared to acrylic, and that it is in development for continued application to mass production.