LGD, Plastic OLED Technology Announcement

LG Display (LGD) is promoting actively as unveiling the plastic OLED technology applied to its own G Watch R.

It is published under the title ‘The New Advancement in Display technology: LG Display’s Plastic OLED’ on the LGD’s U.S Newsroom (http://lgdnewsroom.com/) and the contents are as follows.

The New Advancement in Display technology: LG Display’s Plastic OLED

What is Plastic OLED?

Plastic OLED is an OLED that is made out of plastic substrate. There are 4 very special key technologies applied to this OLED.

1) Plastic, not glass

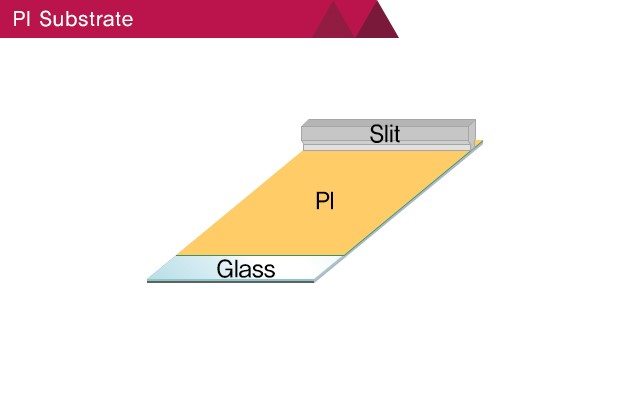

LG Display has shattered the common belief that plastic cannot stand high temperatures, and developed plastic substrate (PI or polyimide) that remains stable under high temperatures and has chemical stability. Moreover, due to the development of the coating process of large format PI, it has become possible to manufacture PI film, which has enabled the plastic curving technology and the technology to eliminate unnecessary bubbles and foreign substances.

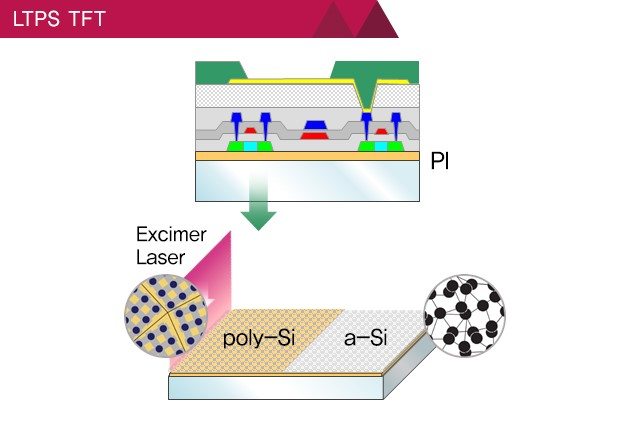

2) LTPS(Low Temperature Poly Silicon) TFT(Thin Film Transistor) technology

One of POLED’s important features is that it can have thin bezel, since the fast electron mobility technology made the integration of different parts to be possible.

3) Flexible Encapsulation Technology to protect OLED elements

With the technology to manufacture inorganic film that prevents water and organic film that prevents alien substances, plastic OLED guarantees the stability of OLED elements.

4) Elimination of Carrier Glass using laser, and adhesionof Back Plate Film

The display surface is relatively clean and neat, as it prevents foreign substance from permeating the surface, by using Laser Source Uniformity technology, alien substance/crack prevention process technology, and flat-panel Back Plate Film and Film Lamination technology.

Why Plastic OLED?

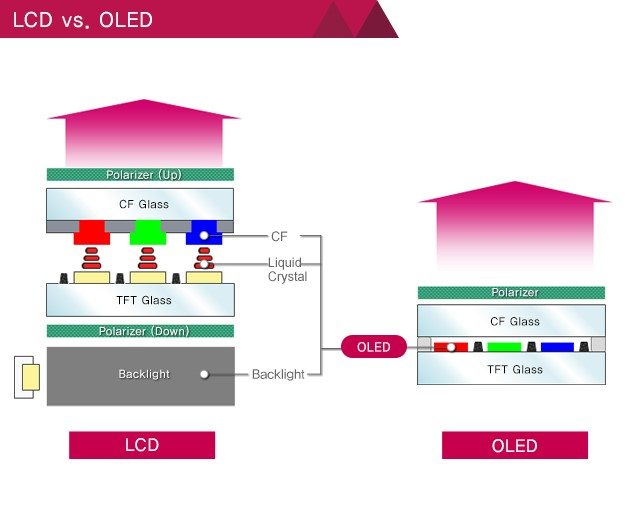

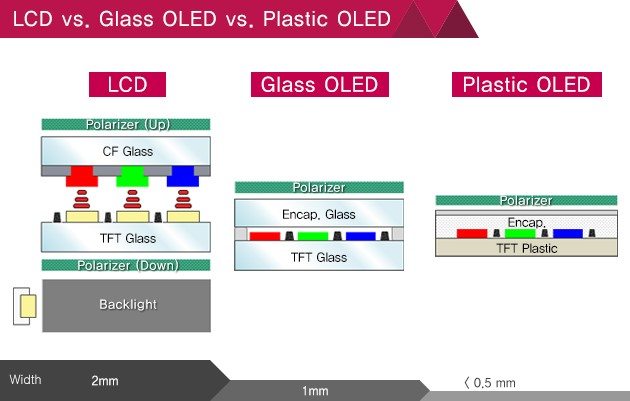

1)Compared to currently existing displays, Plastic OLED has simpler structure. As it can be seen from the diagram below, LCD is composed of many layers of boards, while OLED’s structure is very simple.

2)While glass displays are prone to breakage, Plastic OLED, which is film based, is flexible to be curved to a certain angle, and it does not break easily.

3)Compared to LCD and glass OLED displays, Plastic OLED is thinner and lighter.

The future of Plastic OLED

As Plastic OLED can be applied to curved displays that are bent to a certain curvature, it can be used in various ways, including electronic goods, such as mobile phones, monitors, and TV, as well as cars, wearable devices, and items for interior design.

Other than its design, Plastic OLED is valuable in terms of portability and durability as well. Hence, it seems that Plastic OLED will play an important role in people’s everyday lives in the future.

The Plastic OLED’s potential is very promising. LG Display is devoting its energy and resources to respond quickly to fast growing market and consumers’ needs in order to develop Plastic OLED to become the key OLED application technology in the future.

Source – LG Display Newsroom