[IMID 2018] LG Display, showcased 2-stack RGB OLED for automobile OLED with improved life span.

At IMID 2018 held in BEXCO, Busan on August 29, Kim Kwan-Soo, research fellow of LG Display presented about a new OLED technology for automotive displays.

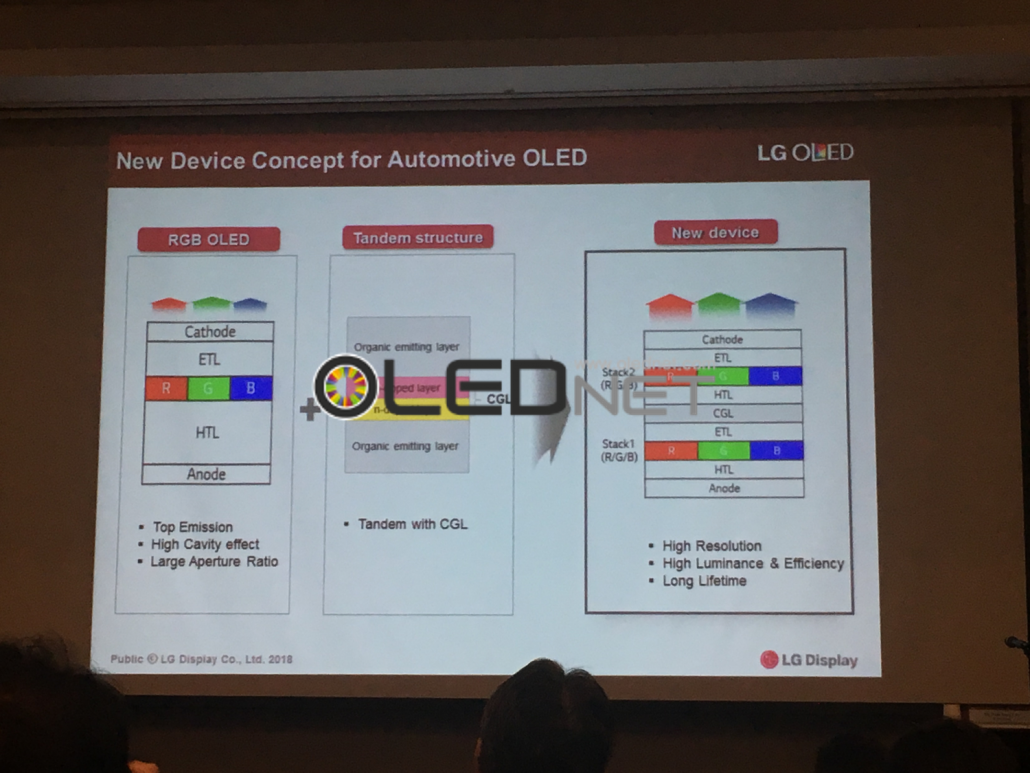

Kim said that RGB OLEDs applied to mobile devices and WRGB OLEDs applied to TVs do not satisfy customers’ needs in terms of life span. To solve this issue, he introduced 2 stack RGB OLED in which RGB OLED has the same tandem structure as WRGB.

Because 2 stack RGB OLED can be thick due to adding a layer of CCL (charge generation layer) to the multi-layer structure, HTL is made thinner than before and the charge balance of the emitting layer is optimized.

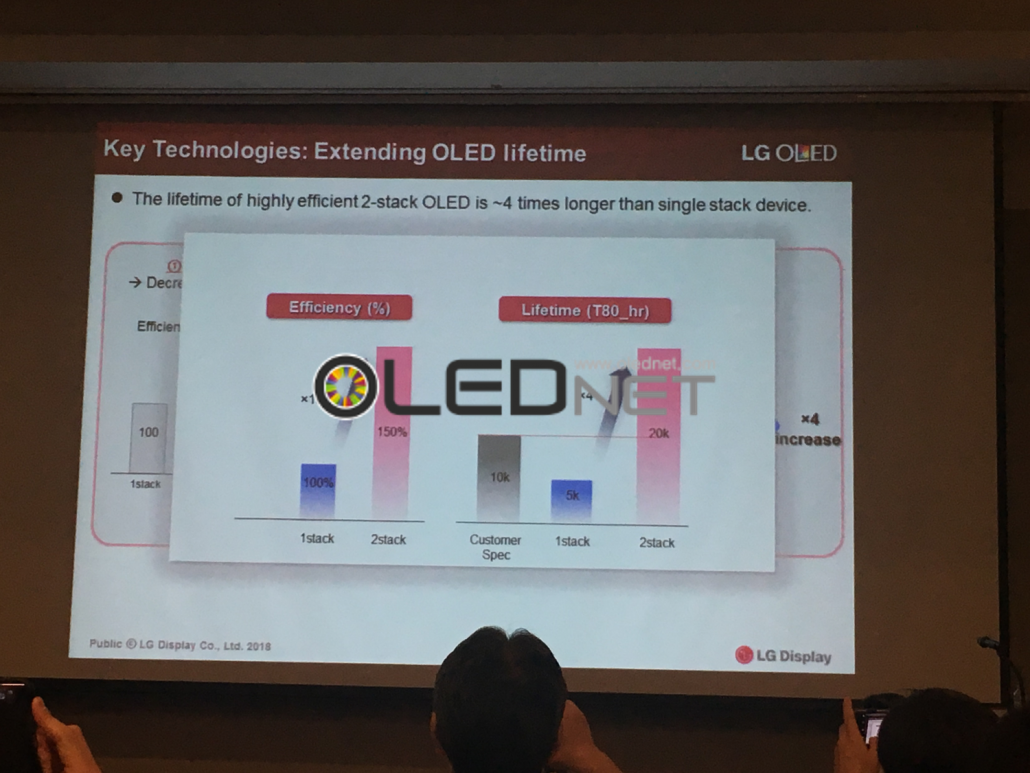

As a result, the 2-stack RGB OLED shows 1.5 ~ 2 times higher emitting efficiency than the 1-stack RGB OLED. Its lifetime is increased by 4 times on T80 basis.

However, the 2-stack structure has a disadvantage in that it has higher power consumption than the general structure. Thus, it is necessary to make efforts to solve this disadvantage.